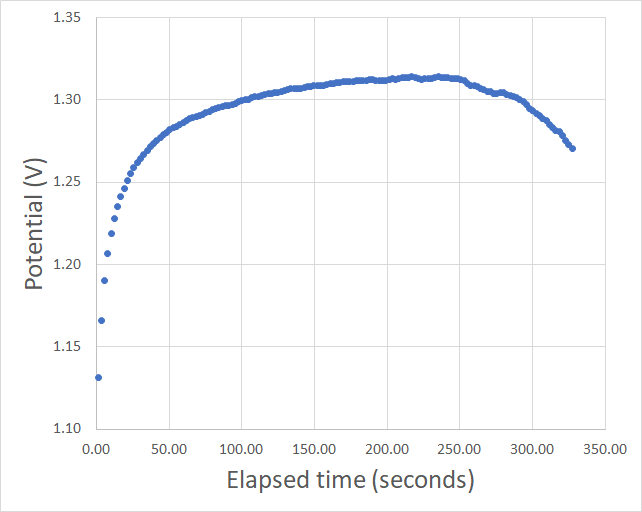

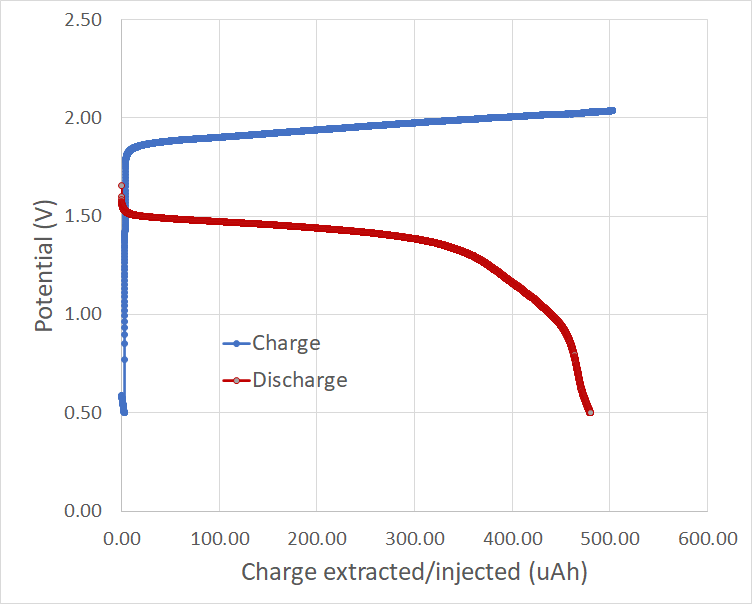

This week I published a post about my first success in the making of a Zinc Bromine battery, this first battery had a Coulombic efficiency of at least 96% and was able to show the expected charge/discharge curves, which I hadn’t been able to see before. In this post I want to talk about some of the problems I have found and the experiments that will follow to attempt to fix them.

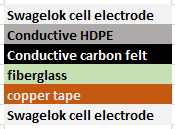

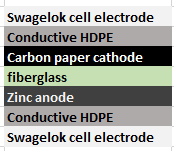

The structure of my current battery is shown above. The first problem I have run into are side reactions due to my use of copper tape as the anode used for zinc plating in the batteries. When I discharge the battery I seem to inevitably get some Cu oxidized and into solution, which is affecting the chemistry of the battery as a function of time. This means that I am losing a lot of coulombic efficiency and my charge/discharge curves are starting to show unwanted side reactions. I will be trying to replace this copper tape anode with a conductive HDPE covering plus a zinc anode to prevent any of these side effects.

The second problem comes from the use of a conductive carbon felt cathode that is pretty heavy (500mg per electrode used in the Swagelok cell) which means that my specific capacity is currently in the 0.5-1 mAh/g of cathode material, when ideally I should be seeing specific capacities in the order of 100-500mAh/g. The battery is already very efficient at using the electrolyte though as the maximum theoretical capacity of it is in the 0.01mAh/uL, given how much zinc and TBAB there is inside of it.

I have ordered an assortment of carbon paper materials (see it here) so that I can test whether these will offer me equivalent power storage with a significantly lower mass. I also ordered the MGL 190 carbon paper (see here) which seems especially promising given that I will be able to build a cathode weighing just 11mg for this area. This should allow me to reach much higher specific capacities if I’m able to sustain the same total capacity for the cell.

When I fully open the cells after going through a full charge cycle I do not observe any accumulation of yellow TBAB tribromide within the interior of the carbon felt electrode. This is telling me that whatever storage is happening is probably only going on within the first few microns of the cathode materials, meaning most of the cathode materials is actually being wasted and not being used for charge storage.

Another problem with the carbon felt is that it has a lot of “loose hairs” that “sneak” into the porous fiberglass separator and cause shorts between the anode and cathode unless I use 4-6 layers of fiberglass I use (which is sadly pretty porous). This substantially increases the internal resistance of the battery and the hairs, although shorting the battery to a much lesser degree, may still be causing an incredible amount of self-discharge given that they do provide significantly shorter paths between the battery anode and cathode materials.

Getting rid of all copper, changing to a zinc anode, covering both anode and cathode with conductive HDPE and changing from a carbon felt cathode to a carbon paper cathode may all be moves that should help me greatly increase the performance of this battery. Stay posted for some further updates!