Over the past year, I’ve collaborated with my colleagues Kirk Smith, Sanli Faez, and Joshua Hauser on developing an open-source flow battery design and kit. Our aim is to make it feasible for most individuals to construct this flow battery with readily available parts that can be either purchased online or fabricated affordably. We’re targeting a price point below 1000 EUR, inclusive of the potentiostat, to ensure accessibility.

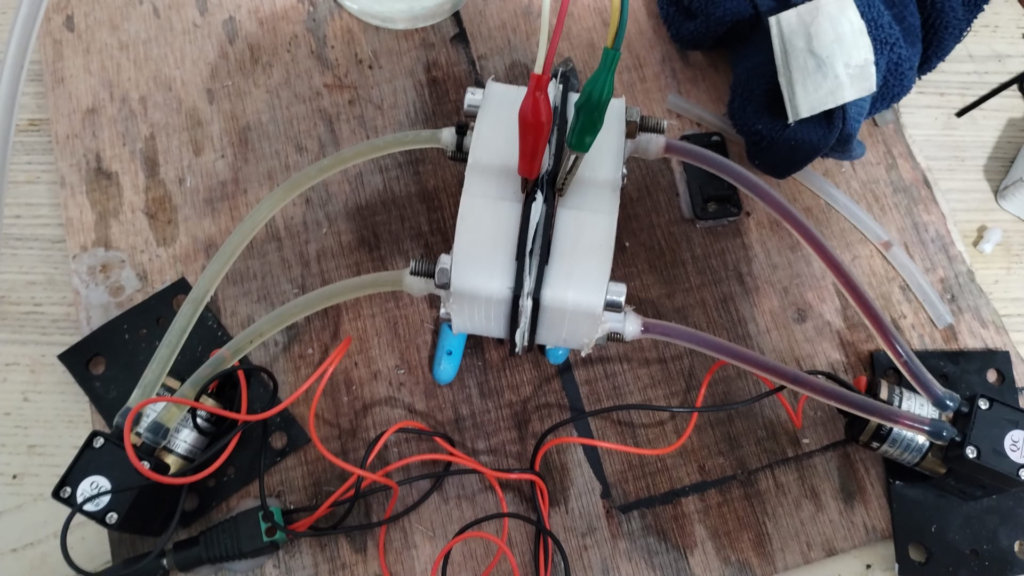

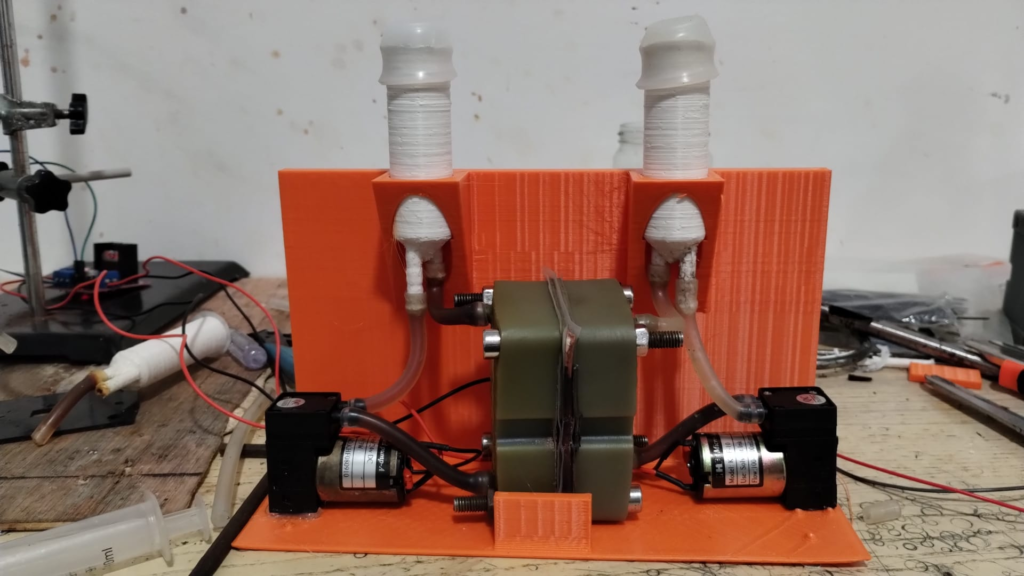

The kit encompasses all necessary components for constructing and utilizing a flow battery for research and development purposes. This includes the battery itself, pumps, electronic components for pump operation, potentiostat, tubing, reservoirs, and a jig for orderly arrangement. Presently, similar setups cost upwards of 9000 EUR, hence our aspiration for significant cost reduction.

Throughout this endeavor, we’ve explored various fabrication methods for our designs, employing FDM and resin 3D printing techniques alongside traditional CNC fabrication. While all three methods are viable, our experiments indicate that the most optimal results are achieved through traditional milling.

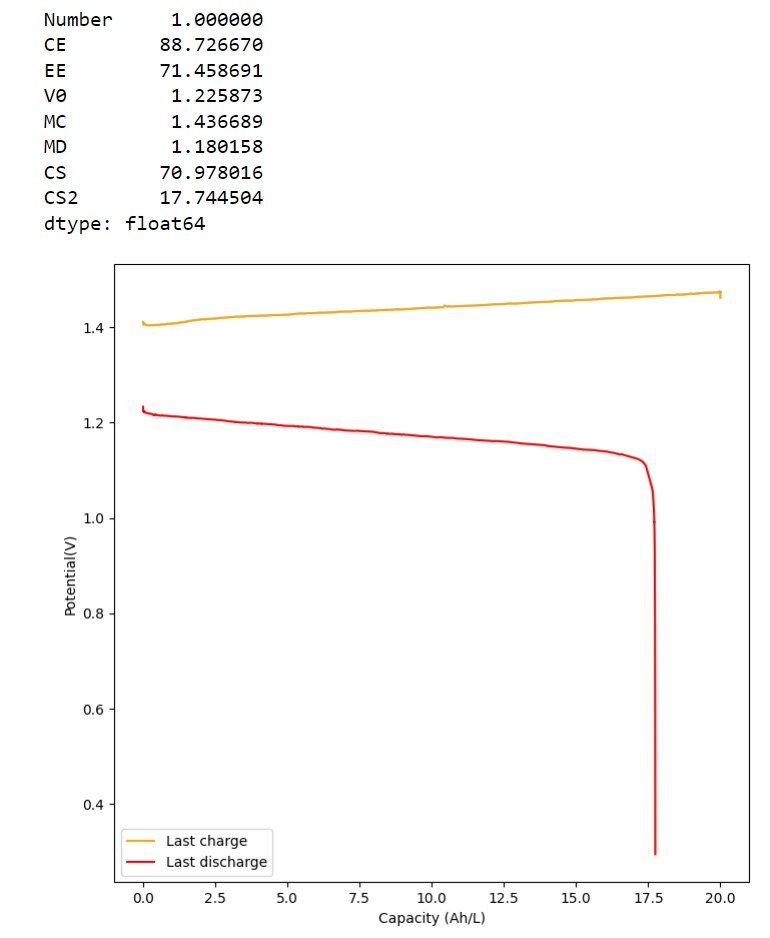

Validation of our design involved utilizing a low-cost photopaper separator and Zn-I chemistry. We’ve achieved successful charge/discharge cycles at capacities ranging from 20-40 Wh/L. However, long-term cycling validation remains ongoing, as we’ve only been testing the final design for approximately a month.

Our design will be presented at the Flow4UBattery Event in Eindhoven, Netherlands, on April 8-9, 2024. You can register here for free, which also includes complimentary lunch (so please make sure you intend to attend if you subscribe). Day 2 of the event will feature a workshop where participants can assemble a flow battery themselves using the design from our kit. Additionally, we’ll be giving away 5 complete kits during the event, each including mystat potentiostats. We’ll also have a fully assembled kit doing cycling so that you can see the fully assembled kit in action!

After this event, we will look into selling these kits online, with all proceeds going towards the development of higher capacity kits with the objective of reaching an open source flow battery stack within the next 2 years. We will also be publishing the full designs and bill of materials online, so that anyone can create their own too!

How does your research compare to something like this-

https://essinc.com

I have seen you have been testing with alternative chemistries like zinc iodide, and at scale ess probably has costs way down and their process well-refined, but they mention “safe water based chemistry”.

@John, ESS is using an all-iron chemistry, with iron plating at the negative electrode and the iron II/III couple at the positive electrode. It’s an elegant system in terms of material inputs (iron salts) but the issue is massive, massive amounts of hydrogen evolution. The secret sauce is in a separate reactor you have to build, to recombine the produced hydrogen (from the negative side) with the iron (III) (on the positive side).

Pingback: Dual Power Supply – An open-source flow battery kit

Pingback: Dual Power Supply – An open-source flow battery kit

This is fascinating. I’m not sure if you’re in need of collaborators or extra engineering hours, but I’d be interested in helping with designs and testing. Email me if keen.

I’m looking for the open source link that works for the kit? Any help would be appreciated.