Although Zinc Bromide is a readily available commodity chemical in some parts of the world (readily available in bulk quantities or for businesses), it is difficult to source in places like the US due to a lack of retail applications to justify its sale to the general public. Small amounts can be bought from sources on ebay/amazon, but the cost can often be above 1 USD/gram with similar costs from Alibaba when buying small quantities (<10kg). For people wanting to do small/medium scale experimentation on Zn-Br batteries, it is often impractical to buy in the necessary quantities, so a low cost synthesis of Zinc Bromide from readily available chemicals is desirable.

The cheapest solution I have found comes from the use of readily available Zinc Sulfate and Sodium Bromide. Both of these salts are available in high purity at very low retail prices (<10 USD/kg even when buying sub kilogram quantities). Since Sodium Sulfate is significantly less soluble than Zinc Bromide, preparing a very concentrated solution containing both salts leads to the precipitation of Sodium Sulfate with Zinc Bromide remaining in solution. The problem with this approach is that the solution always contains a substantial amount of Sodium Sulfate and the many separation/concentration/crystallization steps involved to obtain higher purity ZnBr2 make it a rather impractical approach if higher purity Zinc Bromide is required or if you want to achieve the result quickly.

My solution to this problem is to use a readily available organic solvent – rubbing alcohol – to help speed up the process and achieve better results. Here’s a summary of the synthesis for a small amount:

- In a 50mL tall beaker add ~20mL of distilled water and dissolve 5.5g of Zinc Sulfate Monohydrate and 6.1g of Sodium Bromide. Note that an excess of the Zinc Sulfate is used, as it is the least soluble of the reagents.

- Stir the mix until everything is fully dissolved. All the formed salts should be soluble enough to dissolve in this amount of water at 25C (77F)

- To this solution, add ~20mL of rubbing alcohol.

- Stir the mix for a couple of minutes.

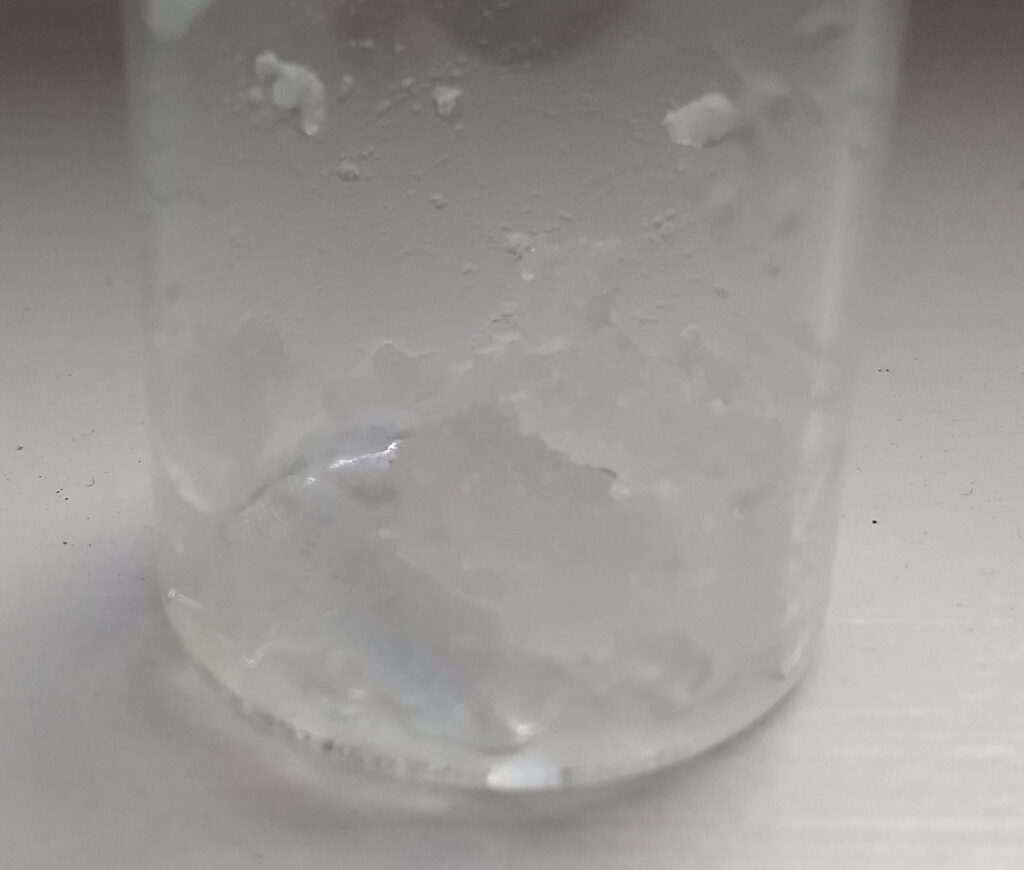

- Let the solution set until everything separates. Three distinct layers should form (one solid, two liquid). The Sodium Sulfate will precipitate and a bottom aqueous layer will form while a top alcohol layer will remain.

- Decant the top alcohol layer and collect it. This layer contains no salts and can be used for future batches.

- Transfer the bottom aqueous phase to another container. The solid precipitate is normally well formed enough as to allow for transferring the bottom aqueous layer to another container without the need for filtering. The remaining solid is sodium sulfate plus the excess zinc sulfate.

- The aqueous layer transferred contains all the Zinc Bromide. You can heat and evaporate most of the water, but bear in mind that the Zinc Bromide will hold very tightly to it and might start to sizzle and “erupt” aggressively as you heat more and more (it’s similar to when water splashes into hot oil). Since the aqueous layer contains some alcohol make sure you do this in an open or very well ventilated space. It is better to reduce the volume until the point where the ZnBr2 starts to crystallize and then transfer it to a desiccator so that it can finish its drying process. A container with anhydrous Calcium Chloride or anhydrous Magnesium Sulfate can do the job.

The above described process – using rubbing alcohol – has the advantage of producing the Zinc Bromide quickly, without the need to perform successive steps of cooling/decanting/filtering/crystallizing, etc. Since both Sodium Sulfate and Zinc Sulfate are almost completely insoluble in alcohol containing solutions – while Zinc Bromide is not – this leads to a significantly faster and more satisfactory synthesis from readily available chemicals. Using a slight excess of zinc sulfate is recommended to avoid the presence of Sodium Bromide in the final solution.

The only tricky part is taking the Zinc Bromide out of the final solution. I prefer not to heat it till it’s completely dry, since the sizzling and “eruptions” of the Zinc Bromide can be pretty aggressive as it tries to hold dearly to every milligram of water it can manage to. Besides, if you heat it to dryness it will quickly become wet again as it cools unless you immediately put it inside a desiccator. It is therefore preferable to put this in a desiccator as soon as Zinc Bromide crystals start to appear and let the drying agent get all the water out of the Zinc Bromide. Note that a desiccator doesn’t need to be anything fancy, some air-tight tupperware you fill with a good enough drying agent can do (the drying agent needs to be more hygroscopic than Zinc Bromide).

I haven’t scaled this process up – as I only work at very small scales – so I don’t know what problems could occur at larger scales. Since it involves alcohol I would advice working at a small scale to see if this process might fit your needs and to be careful and follow all safety precautions.

It’s great that you are putting out info on this. Many people just want to “have a go” at making something small to see what it’s all about and don’t want/need to order kilos of zinc bromide. Using available alternatives is a great way to start. I was in this very situation and was making ZnBr2 with zinc sulfate/sodium bromide in a Pyrex jug placed in the kitchen oven. I now have jars of left over sodium sulfate, which get used as the assist salt in some of my test batteries.

I have since received ZnBr2, TBAB and NaBr to take it to the next level to power something reasonable like a small UPS.

Looking forward to your next post – Cheers.

Thanks for your comment Giancarlo! Do let me know if there’s anything else you would like me to cover.

Did you get the TBAB at a reasonable price? If so, where did you get it?

Thanks

Doug

I bought it on ebay.