In my quest to study Zinc-Bromine batteries, I have been diving deep into this 2020 paper published by Chinese researchers, which shows how Zn-Br technology can achieve impressive efficiencies and specific power/capacity values, even rivaling lithium ion technologies. I’ve found some important things when studying this paper, that I think anyone looking into this technology should be aware of.

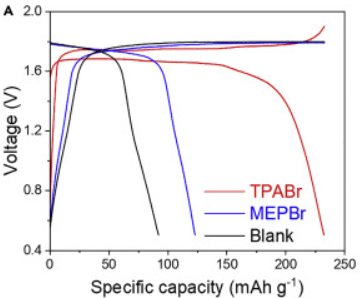

First, let’s talk about the specific capacity values found within this paper. Usually the cells in the study would be charged to a specific capacity of around 500 mAh/g, with Coulombic efficiencies greater than 99% in some cases. The cell used has a diameter of 0.5 inches – which gives us an area of around 1.29032 cm^2 for the electrodes – with the capacity per area at 1.5 mAh/cm^2. This is pretty amazing, because it means we are getting 1.5 mAh out of 3 mg of active material. Wait, what?

The researchers are pretty clear in mentioning that they calculate the specific capacity values given the weight of the cathode but, what they fail to mention explicitly, is that this is not the weight of the entire cathode material but merely the conductive active material within the cathode, which has a carbon loading of 3mg per cathode piece. The real cathode does not weight 3mg, it weights significantly more – probably an order of magnitude more – given that the cathode is prepared using a binder in an 8:1:1 proportion with the carbon sources. This also does not count the weight of the electrolyte or the weight of the anode.

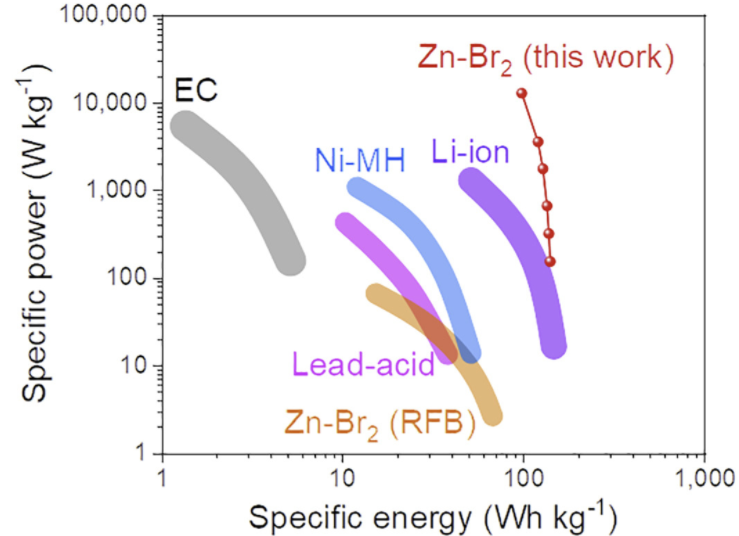

Granted, the above approach is not uncommon in battery research – reporting only capacity values of active materials – but in this case, in the real world, it’s not like you’re going to be getting 250 mAh/g of battery, you’re likely going to be getting a lot less. In the case of the specific power/energy values the researchers take into account the mass of electrolyte and complexing agent (ZnBr2 and TPAB) but they do not account for the mass of the separator, anode, or other materials.

The unfair and potentially misleading part about this is that they are comparing a very partial weight of their Zn-Br system, with the actual values for specific energy and power that have been measured for actual production Li-ion systems. We know of commercial Li-ion systems with specific energy values of 150-250 Wh/kg where that is delivered per actual kilogram of actual battery (including packaging and everything else).

Realistically a Zn-Br fully built battery is likely to have a specific energy way lower than what is published in this paper. So – not very surprisingly – realistic battery systems built with this technology will likely have an energy and power more on the low end of what current Li-ion technology has to offer, although they are bound to be superior to current Zn-Br flow battery designs.

The paper and Zn-Br technology are still extremely interesting – at least to me – because of the high efficiencies, way lower discharge rates, higher specific energy/capacities and other advantageous properties over traditional Zn-Br flow batteries, but they are unlikely to be a game-changer in the energy industry. As most of the time, researchers want to make their numbers look as good as they can within the general practices of the field and battery research is not the exception. I’m not saying that the researchers are being unethical or lying, just that the reader must be aware of how researchers report these numbers and how they compare to what you actually get in final products.

With that said, the confusion from how specific capacity/energy/power are measured in battery research is not without controversy. With some important efforts going on (see here) to try to create clearer standards within the field to avoid confusion.

Hi – I have a research project for this topic and I need some consulting help.

Would you be interested? Please let me know. Thanks.