In my previous posts about cation exchange membranes, I created a membrane using cross-linked PVA over a cellulose support. For this purpose, I used a filter paper and then applied successive layers of a solution with PVA, phosphoric acid and citric acid, which I then heated to 150C to create the final cross-linked membrane. This procedure created a membrane that had high permselectivity, decent in-plane conductivity and that could be produced for very low cost.

The problem however, came from the fact that the membrane degraded in the presence of Mn3+ , which was generated when the Mn|Fe chemistry I am testing is cycled. The degradation became apparent as the red color of the Mn3+ faded with time, although no crossing of the Mn3+ across the membrane happened. There were also a lot of bubbles generated on the membrane on the Mn side, which is further evidence supporting this degradation mechanism.

I think that this degradation happened mainly because of the cellulose, which is the most reactive part of the structure. To try to alleviate this problem, I decided to move away from the cellulose support and try to cross-link the PVA over a more stable substrate. To achieve this I performed the same cross-linking process, but this time doing it over a daramic polyethylene separator as support.

The Daramic is a microporous polyethylene separator – commonly used in lead acid batteries – which can be purchased for very little cost (only a few dollars per square meter). The daramic has a well defined pore size that can be filled with the PVA solution. Upon heating and reapplication of the solution, the pores can be filled with the cross-linked cation exchange material, with the daramic matrix providing the main source of structural support.

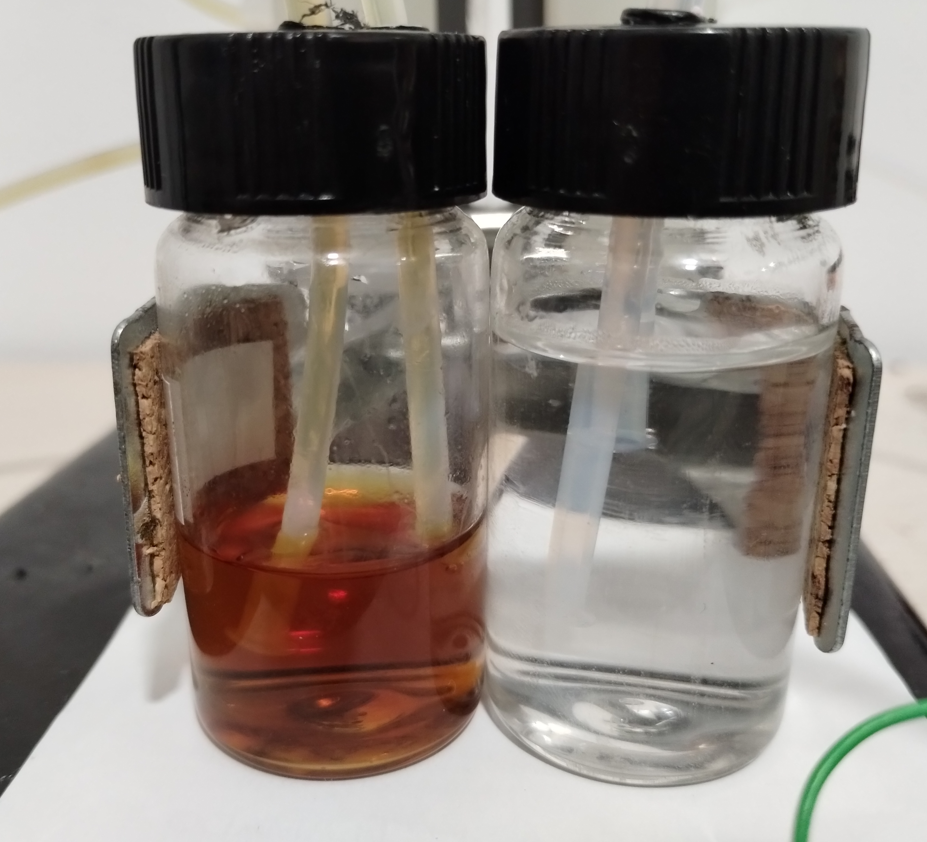

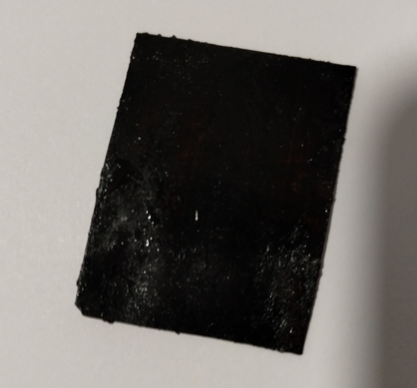

After the material has been saturated, heated to dryness and resaturated/redried multiple times with the polymer solution (10mL 14% H2SO4, 15g PVA, 8g citric acid, 250mL of water), the Daramic is then heated to 150C for one hour to finalize the process. The Daramic film created is black and has a permselectivity greater than 95%, measured in a cell with 0.1M KCl | 0.5M KCl. The first image in this post also shows how absolutely no cross-over of an Fe-EDTA salt is seen after running by this PVA+Daramic separator for more than 24 hours. When using just the Daramic microporous separator, cross-over is seen within minutes.

The great news is that the Daramic support is made of polyethylene, so it is very unreactive. The crosslinked PVA is also way less reactive than the cellulose, enough so that it now doesn’t react with Mn3+. I generated some of this material through electrolysis of an Mn-EDTA solution, and the crosslinked daramic didn’t bubble or degrade the Mn3+ after a couple of hours.

Sadly my potentiostat broke due to a small lab accident (spilled liquid over it), so I am waiting for a new potentiostat to be delivered to perform the first cycling experiments using this new cation exchange separator.

Hey, I just had yesterday a very similar idea. I didn’t know about Daramic, so instead I was contemplating using either a polypropylene mesh or cloth, or fiberglass cloth. Basically going off the idea of reinforced concrete, only using an inert mesh instead of rebar and phosphorylated PVA for concrete. 🙂 I plan next week on doing some experiments with that, with either your formula for PVA, or the one in the article I mentioned in the reply to your previous post (I do have a vacuum chamber).

Also, did you use sulfuric acid instead of phosphoric this time?

Yes, I used sulfuric, I had just ran out of phosphoric acid, but it should work with either as the acid is just acting as a catalyst here.

Interesting. I was under the impression that sulfonated PVA is extremely water-soluble.

Anyway, I’m all set to begin some experiments of my own, using the PVA+H3PO2 method from the paper I posted. I will run several batches, one plain, one crosslinked with paraformaldehyde and one crosslinked with glyoxal. I have a large outdoors area that I use for experiments so no worries about fumes. I prepped my vacuum chamber and I’ll keep it wrapped in an electric blanket for 3 days, then heat-treat at 120C for 3h as they recommend. It will be interesting to see which of the 3 formulations is better. And if they’re not mechanically stable enough without reinforcement/support, I have some extra-fine fiberglass cloth that I can embed in the film.

(my goal is not battery research but preparative electrochemistry in split-cells, though it has led me to the same membrane conundrum)

Thanks for your reply. This is not sulfonated though, the sulfuric acid is too dilute to do any meaningful sulfonation of the polymer. Rather, the cation exchange capacity comes from the citric acid when it crosslinks with the PVA. Once the PVA is crosslinked with the citric acid, the solubility drops dramatically.

So far my membranes seem to be going fine. I left them to cure for 3 days in the vacuum chamber, kept warm. I had to put a beaker with dessicant (NaOH powder) in the chamber, and open it every day to wipe up the condensed water within, but all the water from the Petri dishes I used to form the membranes has evaporated and there is a thin membrane at the bottom of each. I find it interesting that the ones with crosslinking agents (PFA, glyoxal) have shrunk and are a smaller diameter than the dishes, whereas the ones without crosslinking haven’t. Anyway I’ll let them air-dry outside the chamber for another day or so then heat-treat them. They do still feel a little too moist. They are very thin, at most 1/4mm I estimate. These I didn’t add any reinforcing to, just PVA+H3PO2 +/- crosslinker. Each dish started with 35ml of the initial mix, +/- 1ml.

Nice! I was never able to do this because when I demolded they always broke, films like these are just too sensitive for my fabrication skills.

Where can i buy daramic in small quantities?

About your potentiostat issues, I have found a nice project to build your own for little cost.

https://www.sciencedirect.com/science/article/pii/S0013468622005618?via%3Dihub

https://github.com/PeterJBurke/Nanostat

The supply issues that they mention seem to be resolved now, the analog frontend chip LMP91000 is now in stock at Mouser in the thousands of pieces for $5 each: https://www.mouser.com/ProductDetail/Texas-Instruments/LMP91000SD-NOPB?qs=OYMYEaN9QmAbnRLMZUYFgA%3D%3D

Also you don’t have to build a whole custom board, you can simply use an ESP32 devkit board which you can get for under $10 in places like Amazon, and just make a very small daughterboard just for the LMP91000 that you connect to it.

My custom membranes are still drying, I’m very busy at work and won’t have time to do the heat treatment and testing until next week. A couple of them have detached by themselves from the polystyrene Petri dishes bottoms so I don’t anticipate having any issues removing the rest of them from the moulds.

Thanks for writing. Sadly the nanostat does not have the necessary galvanostatic capabilities for battery cycling.

I have also now obtained a new potentiostat. I had it built based on this design https://www.sciencedirect.com/science/article/pii/S2468067220300729

I baked the membranes 120C for 3h. This is what they looked like at the end:

https://i.postimg.cc/bww5P6mw/IMG-20230619-130715.jpg

https://i.postimg.cc/C1sCz01T/IMG-20230619-134745.jpg

Top 2, not crosslinked (only PVA+H2PO2); middle, with added paraformaldehyde; bottom, with added glyoxal.

The no-crosslinker-added ones warped quite a bit but are still soft and pliable. The PFA ones warped only a bit, they are much stiffer but still pliable. The glyoxal ones have not warped at all, are much darker than the others and are very stiff. They’re also more uneven than the others, thicker in the middle and thinner around the edges (the others remained fairly even).

I’ll let them equilibrate at room temperature for a while then put them in a very dilute solution of phosphoric acid to swell

Incredible project!

I was looking for good ion exchange membranes to DIY and I found your blog.

How many times exactly did you made the cycle of saturation and dryness? Or it something that you need to constantly monitor with your equipment in order to get it right?

Thanks for commenting! Usually 4-5 cycles of saturating and drying are needed before curing for an extended time at the final temperature. The more cycles you do the better your permselectivity but the worse your conductivity, so you should experiment and find which number works best for your particular application.

Sorry for question this here, but I couldn’t find an email to directly contact you.

Some time ago I saw an Alkaline Ion Exchange Membrane for an Alkaline Fuel Cell:

https://youtu.be/BT3HjyziH_0

The method in the video:

The membrane is made using 10g of PVA (polyvinyl alcohol) 5g of PVP (polyvinyl pyrrolidone) mixed with water, molded into shape until dry with no bubbles, prensed between two glass plates for 24h for optimal surface.

Then 20ml of glutaraldeyde (2%), 10 drops of HCL (Chloridric Acid) and 40ml of pure acetone will be mixed in a crosslink solution in which the membrane will be submerged for 40 minutes for the crosslinking reaction to occur and transform the membrane in some hydrogel looking material.

Lastly, a solution made with 50 ml of water, 8.6g of KOH where the membrane will bath is then heated up to 60ºC for 3 hours until the membrane gets a brownish colour

Which made me curious to see how well would this membrane work, since your membrane is less complicated than this one, but performs as good as a Nafion.

From the description itself, you would say that this membrane is more or less as good as yours?

I don’t know how my membrane would compare against that one, you would need to prepare them and make the measurements. Also, while the membrane described here performs as well as Nafion regarding permselectivity, it likely significantly underperforms Nafion in terms of both electric conductivity and durability.